Sicherstellung der Gerätezuverlässigkeit mit dem Bently Nevada Vibrationssystem

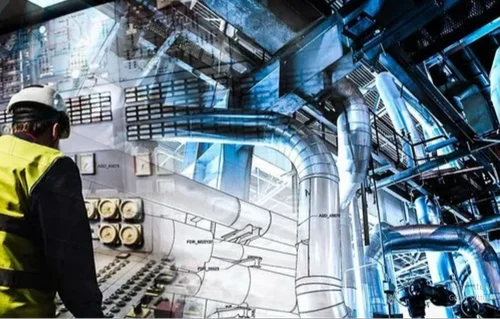

Das Bently Nevada Vibrationssystem spielt eine entscheidende Rolle bei der Aufrechterhaltung der Gesundheit von Anlagen in Branchen wie Öl und Gas. Dieses fortschrittliche System misst nicht nur Vibrationen; es verfolgt auch Geschwindigkeit, Wellenposition und Temperatur. Diese Messungen liefern wichtige Einblicke in den Betriebszustand von Maschinen. Lassen Sie uns erkunden, wie dieses System die Zuverlässigkeit von Anlagen verbessert und kritische industrielle Prozesse schützt.

Echtzeitüberwachung verhindert Ausfälle

Die kontinuierliche Überwachung ist das Fundament des Bently Nevada-Vibrationssystems. Durch die genaue Beobachtung der Gerätevibrationen werden Probleme identifiziert, bevor sie eskalieren. Wenn beispielsweise die Vibrationen die normalen Werte überschreiten, warnt das System die Betreiber sofort. Dies ermöglicht eine rechtzeitige Intervention, wodurch das Risiko kostspieliger Ausfallzeiten oder katastrophaler Fehler verringert wird. Echtzeitdaten sorgen dafür, dass die Wartungsteams proaktiv statt reaktiv bleiben, was die gesamte Betriebseffizienz erheblich verbessert.

Umfassender Schutz durch Multifunktionalität

Das Bently Nevada-System geht über die Vibrationsüberwachung hinaus. Es misst die Wellenposition, -geschwindigkeit und -temperatur und bietet einen ganzheitlichen Überblick über die Maschinenzustände. Abnormale Wellenbewegungen deuten häufig auf Ausrichtungsprobleme oder Verschleiß hin. Geschwindigkeitsvariationen können auf mechanische Fehlfunktionen hinweisen, während ungewöhnliche Temperaturspitzen auf Schmierungsprobleme hindeuten. Durch die Berücksichtigung all dieser Parameter gewährleistet dieses System einen umfassenden Schutz der Ausrüstung und ist ein unverzichtbares Werkzeug für die Öl- und Gasindustrie.

Entscheidungsfindung mit genauen Daten verbessern

Genauige Daten fördern bessere Entscheidungen. Das Bently Nevada-Vibrationssystem liefert präzise und zuverlässige Messungen, die es Ingenieuren ermöglichen, Muster zu erkennen und potenzielle Probleme vorherzusagen. Wenn beispielsweise die Vibrationsmuster allmähliche Anstiege im Laufe der Zeit zeigen, können die Betreiber Wartungsarbeiten planen, ohne die Produktion zu stören. Dieser datengestützte Ansatz minimiert das Rätselraten und maximiert die betriebliche Zuverlässigkeit.

Kosten senken und Lebensdauer von Geräten verlängern

Ungeplante Wartung führt oft zu höheren Kosten und längeren Ausfallzeiten. Das Bently Nevada-Vibrationssystem hilft, solche Szenarien zu verhindern, indem es vorausschauende Wartung ermöglicht. Durch die frühzeitige Behebung von Problemen sparen Unternehmen Reparaturkosten und vermeiden ungeplante Stillstände. Darüber hinaus reduziert die kontinuierliche Überwachung den Verschleiß und verlängert die Lebensdauer kritischer Maschinen. Im Laufe der Zeit führen diese Vorteile zu erheblichen Kosteneinsparungen und gesteigerter Produktivität.

Abschluss

Das Bently Nevada-Vibrationssystem ist mehr als ein Überwachungswerkzeug; es ist ein Game-Changer für die Zuverlässigkeit von Anlagen. Durch die Bereitstellung von Echtzeitdaten, multifunktionalen Fähigkeiten und nahtloser Integration ermöglicht es den Branchen, reibungslose und effiziente Abläufe aufrechtzuerhalten. Dieses System schützt nicht nur Maschinen, sondern fördert auch Kosteneinsparungen, Nachhaltigkeit und langfristige Produktivität. Während sich die Branchen weiterentwickeln, werden Werkzeuge wie das Bently Nevada-System unverzichtbar bleiben, um den Erfolg sicherzustellen.